In the chemical, petroleum, and energy sectors, the flash point remains a critical safety parameter for evaluating the flammability of liquids. Over the years, multiple flash point testing methodologies have been developed to address evolving industry requirements.

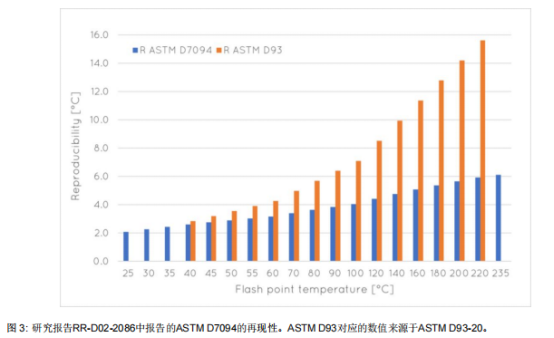

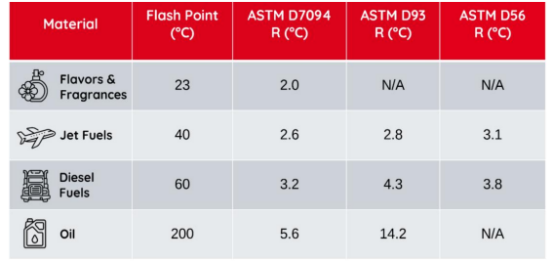

The most recent standard, ASTM D7094, was subjected to an extensive interlaboratory study (ILS) to evaluate its precision across modern fuels, blends, and chemicals. Findings published in Research Report RR-D02-2086 demonstrated that ASTM D7094 delivers the highest reproducibility among all recognized flash point methods. This establishes eralytics’ eraflash as the industry benchmark—offering a safe, reliable, and highly accurate solution for flash point testing in today’s demanding petrochemical applications.

Conventional closed-cup flash point methods, such as ASTM D93 (GB/T 261), remain widely used but present notable limitations. These include the need for a large 75 mL sample volume and the use of an open flame ignition source, which introduces safety risks during testing.

By contrast, the ASTM D7094 method requires only 2 mL of sample and operates in a fully sealed environment, thereby eliminating open flames and significantly enhancing laboratory safety. In addition, ASTM D7094 delivers results at twice the speed of ASTM D93, offering both efficiency and reliability in routine petrochemical testing.

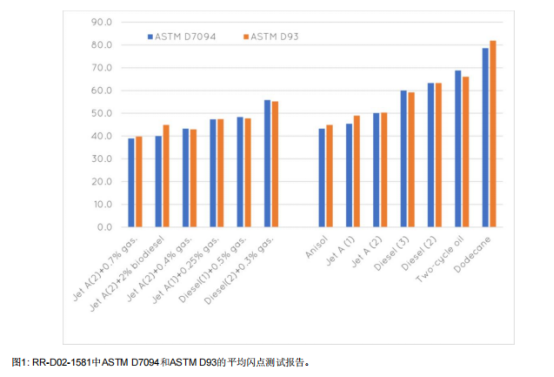

In 2004, interlaboratory studies (ILS) confirmed that the ASTM D7094 method delivers results consistent with ASTM D93, showing no statistically significant deviations between the two.

The newly released ASTM D7094-25 integrates findings from Research Report RR-D02-2086, which highlight the method’s enhanced reproducibility. The improvements are especially significant at elevated temperatures, where precision variations are reduced by more than a factor of two compared to previous methods.

Comprehensive high-precision data from leading standardization laboratories validate that the ASTM D7094 method delivers higher reliability than other established flash point testing techniques.

eraflash flash point tester:

- Offers the best precision over the widest temperature range even for contaminated Samples.

- Inherently safe – no open ignition source (gas flame or glowing wire) is used eliminating the risk of fire hazards in the laboratory

- Twice as fast compared to ASTM D93 with the help of eralytics PBT® - Peltier Boost Technology

- Uses only 2 mL of sample, minimizing waste and significantly speeding up cleaning procedures and thermal regulation.