Location position:Products

>

<

eraflash

Category: Others

Method Standard: ASTM D6450, D7094, IP620,ASTM D396, D975, D2880, D3699, D7467

Application: Lubricants Condition Monitoring

Brand: Eralytics

Hotline:

021 - 63175588

Products description

Products characteristic

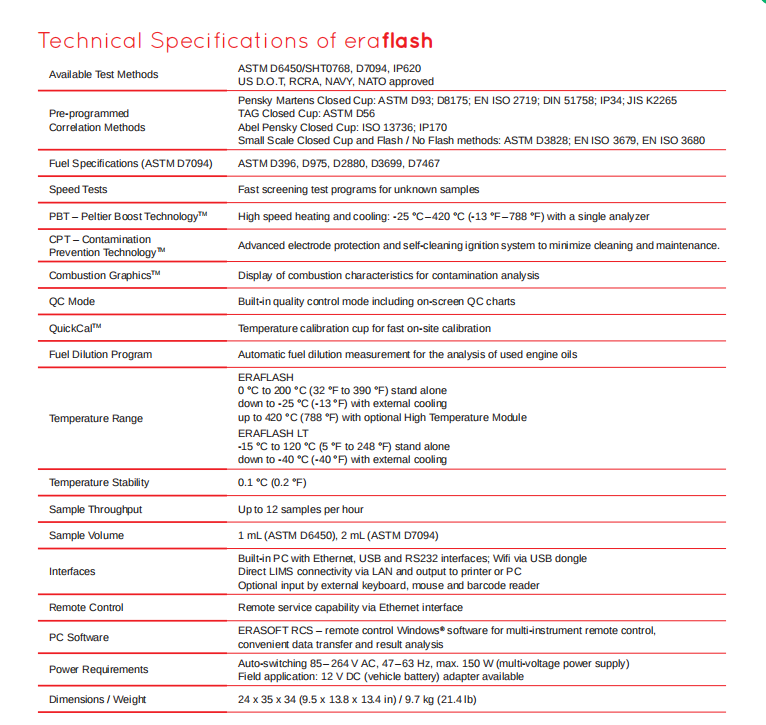

technical specification

The flash point tester ERAFLASH measures in full compliance with the Continuously Closed Cup flash point testing methods ASTM D6450, ASTM D7094 as well as the European equivalent IP620. ASTM D7094 shows no statistical bias to the former ASTM D93 Pensky Martens method. The sample volume is only 2 ml. During measurements an electric arc ignites the sample vapor and the analyzer determines the flash point by the pressure change inside the closed cup. Flash point testing never was safer and easier.

The innovative Continuously Closed Cup Flash Point (CCCFP) methods ASTM D6450 and D7094 use only 1–2 mL of sample that is sealed in a closed chamber during the whole measurement process. An electrical arc inside the chamber ignites the sample and the lack of oxygen extinguishes the flame automatically. The device measures the corresponding pressure increase inside the chamber. An increase of ≥ 20 kPa is defined as the flash point.

eralytics’ patented PBT – Peltier Boost TechnologyTM allows previously unmatched heating and cooling rates. A sophisticated mechanism safeguards the Peltier elements from high temperatures during heat-up and allows their use during cooldown even at temperatures that would normally harm them. This cleverly designed temperature control system allows turnaround times that are significantly shorter than those offered by all other flash point instruments available on the market.

PBT also facilitates the widest measurement range on the market within a single device. The powerful Peltiers reach -25 °C and the safeguard mechanism efficiently shields them from temperatures up to 420 °C. The low temperature model ERAFLASH LT even reaches -40 °C oven temperature at significantly faster cooling rates than ever before.

ERAFLASH is the flash point testing solution for a wide variety of industries. It is used for specifying fuels, analyzing fresh and used lubricating oils, and bitumen testing. The small sample volume also renders it ideal for the more expensive samples such as flavors & fragrances, cosmetics, paints and varnishes or even hazardous waste.