Location position:Products

>

<

CINRG CS-APC-2 Automated Particle Counter

Category: Others

Method Standard: ISO 4406,SAE AS4059,NAS 1638

Application: Lubricants

Brand: CINRG

Hotline:

021 - 63175588

Products description

Products characteristic

technical specification

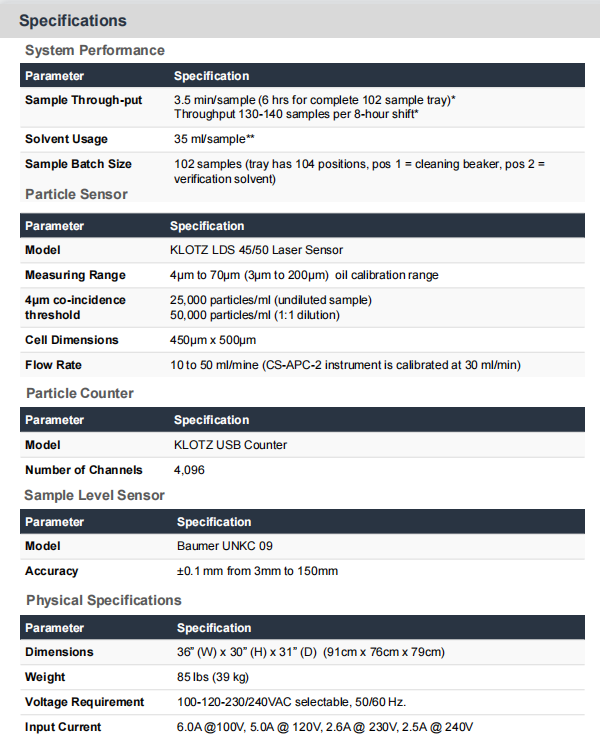

The CINRG CS-APC-2 particle counting system is a fully automated system that meets the requirements of ASTM D7647-10 in which oil samples are diluted with solvent prior to testing in order to eliminate interferences from” soft” particles such as water, varnish and suspended liquid additives.

The system combines equipment from several leading equipment manufacturers with some innovative technology and sophisticated software that was developed by Wearcheck for use in their oil Analysis laboratory. The system has a high degree of flexibility and can be customized to a large extent to suit local laboratory processing requirements.

- The system complies with ASTM D7647-10. Dilution of oil samples with solvent prior to testing to eliminate interference from soft particles such as water, paint films and suspending liquid additives

- The homogenized sample can be quickly injected into the 2oz (32mL) sample cup on the 104-position injection tray, and the sample can be processed in batches No need to manually adjust the sample accurately, the system automatically measures the sample volume in the sample cup with an accuracy of up to ±2% (before dilution)

- It is also possible to enter the sample batch file to add or remove samples after sample processing has started. During sample processing by the instrument, a sample can also be pulled out of the sorting queue for priority processing. You cannot edit batch files that have already processed samples, and you cannot edit samples that are currently being processed.

- A suffix can be edited to indicate the comparison of the counts against a user-defined upper and lower limit range (4µm, 6µm and 14µm) to determine acceptable system performance. Following an unsatisfactory result relative to the process control criteria, the system parameters control subsequent processes.

- The output file format is defined in the sample batch file, and exported data can be easily customized using system parameters. In addition to the inherent system parameters, the output file can include solvent background counts, sample volumes, sample dilution rates, and all raw count data.

- Sample throughput: 4-5 minutes per sample Solvent dosage: 40 ml per sample

- Sampling tray: 102 samples (the sampling tray has 104 positions, the 1st position is the cleaning beaker, and the 2nd position is the verification solvent)

- Particle Counter Model: KLOTZ LDS 45/50 Laser Sensor

- Measuring range: 1.5µm-100µm

- Flow rate: 10-50ml/min (CS-APC-2 calibrated to 30ml/min)

- 4µm meets count threshold: 25,000 particles/ml (undiluted sample) 50,000 particles/ml (1:1 dilution)